The purpose of a guard is to protect people from hazards associated with machinery. Guards also protect people from injuries that occur due to fatigue, distraction, and other forms of human failure. The illustrations below depict various hazards that may be encountered in industry.

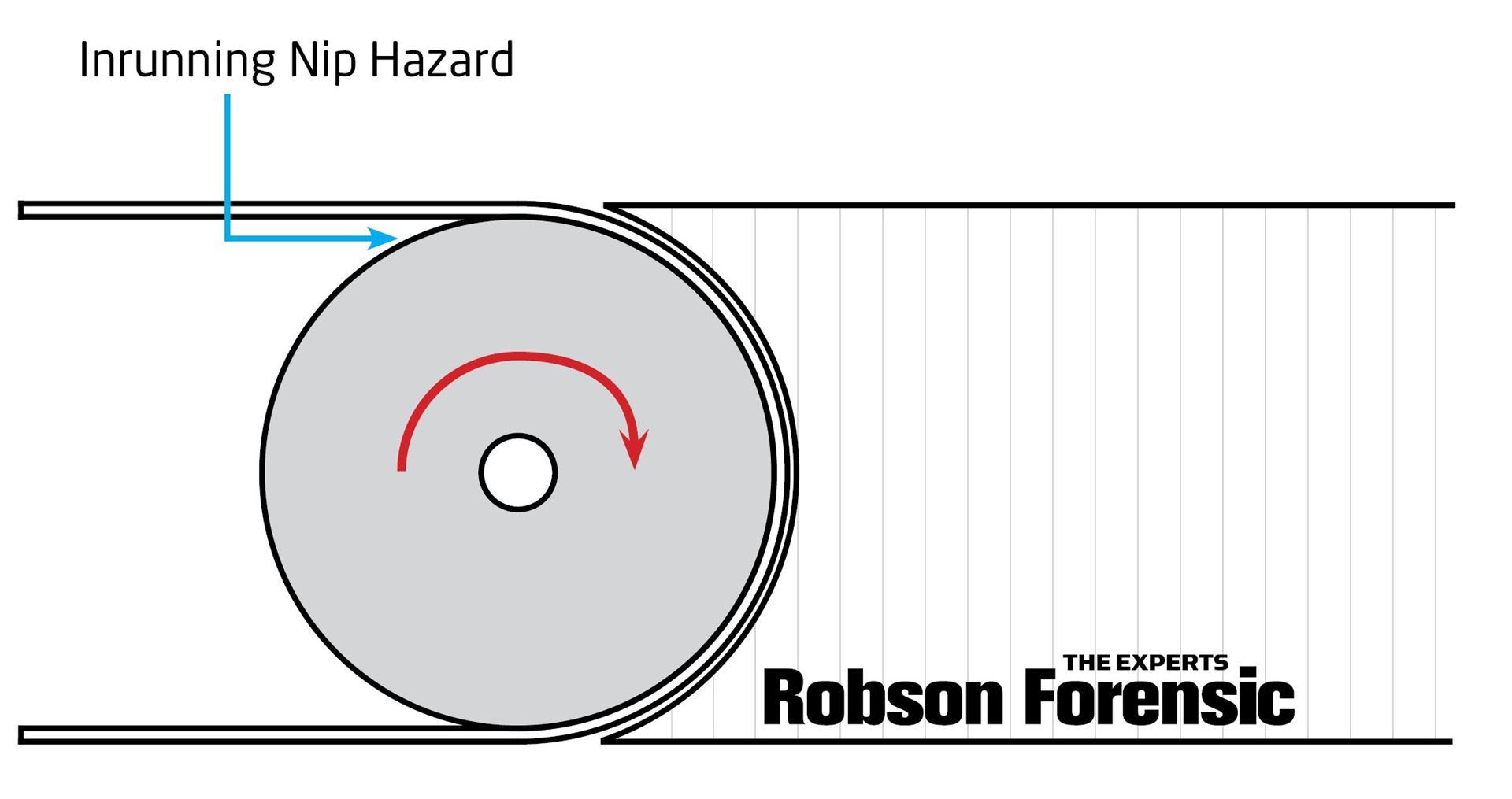

Inrunning Nip Hazards

Inrunning Nip Hazard Example

Inrunning Nip Hazard Example

An inrunning nip point is created by a mechanism having one or more rotating parts. Wherever parts rotate over, under, or near a stationary object, or wherever machine parts rotate in contact with or near other rotating parts (in opposing directions) an inrunning nip is formed. The danger of the inrunning nip hazard is that it draws objects into the mechanism, entrapping, and often flattening them. It can be difficult, if not impossible, to withdraw entrapped body parts from these hazards.

Shear Hazards

%20shear%20hazard.jpg) Shear Hazard Example

Shear Hazard Example

A shear hazard is created where two machine parts move across each other or move closely enough to cut or move an object that enters the system. Shear hazards frequently exist in machinery and equipment designed for cutting or punching.

Crush Hazards (Pinch Point hazard)

%20crush%20hazard.jpg) Crush Hazard Example

Crush Hazard Example

A crush hazard is created where two objects move toward each other or when a moving object approaches a stationary object. Injuries occur where body parts get caught or crushed between two parts/objects. Crush hazards frequently exist in machinery or equipment designed to bend, stamp, or form metals.

Snag Hazards

%20Snag%20hazard.jpg) Snag Hazard Examples

Snag Hazard Examples

A snag hazard is created where rotating or reciprocating equipment includes protrusions that can catch or snag on clothing or other passing objects. Snag hazards have the potential to quickly draw a person into moving equipment, creating entanglement hazards. They can also tear flesh or dismember body parts depending on their size, shape, and sharpness. While projections on rotating shafts can catch or snag clothing, a bare rotating shaft can present a snag hazard as well.

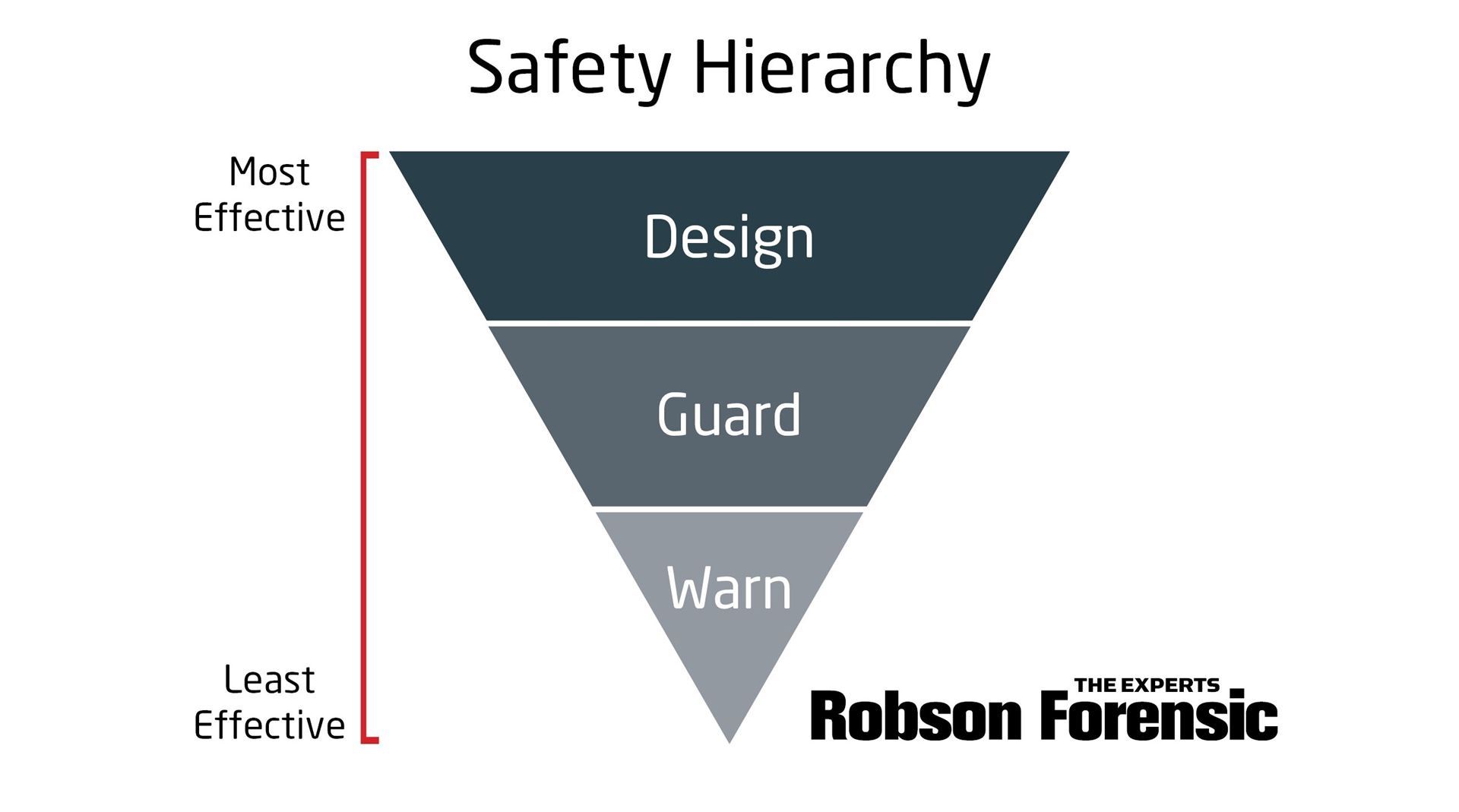

INDUSTRIAL MACHINE SAFETY

Manufacturers must assure that hazards are engineered out of the product during the design process. If a hazard is inherent and cannot be designed out of the machine, system, or process, the hazard must be guarded. In all cases, the user must be warned or instructed about dangers of the product. These steps form the fundamental principles and rules of practice for the safe and appropriate engineering of products, and are sometimes referred to as the hierarchy of hazard control.

The requirement for guarding and, more broadly, machine safety is reinforced by a number of government and industry oversight organizations.

The requirement for guarding and, more broadly, machine safety is reinforced by a number of government and industry oversight organizations.

Robson Forensic possesses an extensive technical library that houses standards and reference materials dating throughout the modern industrial era. Our experts provide forensic investigations on behalf of both plaintiffs and defendants involving a broad range of industrial, commercial, and consumer products.

For more information, access the complete article at

www.robsonforensic.com/guarding